Defective children's products pose significant risks, including choking, strangulation, burns, and even fatalities due to hazardous materials, design flaws, unsafe closures, or mechanical malfunctions. Recalls are vital in protecting kids from these dangers, educating consumers, and driving improvements in manufacturing and regulations. Effective recall processes involve robust quality control, proactive monitoring, clear procedures for identifying defects, collaboration with regulatory bodies, efficient distribution, compensation or replacements, and educational resources. This not only satisfies consumers but also creates a safer marketplace, reducing injuries linked to defective children's products.

In the realm of consumer safety, particularly concerning our youngest members, understanding and addressing defective children’s products is paramount. These items, due to manufacturing flaws or design deficiencies, pose significant risks to kids’ well-being. This article delves into the critical importance of recalls as a protective measure against defective children’s products. We’ll explore how recalls mitigate hazards, discuss their impacts on consumer protection, and highlight best practices for ensuring safer products in families’ homes.

- Understanding Defective Children's Products and Their Risks

- The Role of Recalls in Ensuring Product Safety

- Impacts and Best Practices for Consumer Protection

Understanding Defective Children's Products and Their Risks

Defective children’s products pose significant risks to young users due to their developing bodies and tendency to engage in exploratory play. Such items can range from toys with hazardous materials or design flaws, to clothing with unsafe closures, and even baby equipment with mechanical malfunctions. The consequences of these defects can be severe, leading to injuries such as choking, strangulation, burns, or even fatalities. Furthermore, the impact extends beyond physical harm; cases of caregiver abuse and neglect may arise when products fail to meet safety standards, putting children at greater risk in their care environment.

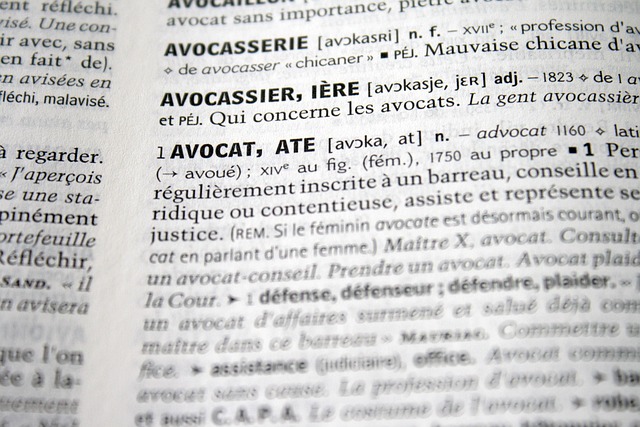

A breach of fiduciary duty by manufacturers and retailers who fail to ensure product safety can have dire repercussions. This includes not only legal liabilities for truck accident injuries but also the broader societal impact on child development and welfare. Understanding these risks is paramount in driving the necessary recalls to protect children and hold accountable those responsible for putting defective products into the market, ensuring a safer environment for kids to grow and play.

The Role of Recalls in Ensuring Product Safety

Recalls play a pivotal role in safeguarding the well-being of children exposed to defective products, acting as a critical safety net. When a product is recalled due to defects that could potentially harm young users, it triggers a series of actions aimed at mitigating risk. Manufacturers are obligated to remove these unsafe items from the market, preventing further exposure and potential injuries or fatalities. This proactive measure ensures that parents and caregivers can trust that the products they purchase for their children meet stringent safety standards.

The impact of recalls extends beyond product removal. They serve as a powerful tool for education and awareness, encouraging consumers to stay informed about potential hazards and take immediate action if their products are affected. In cases involving defective children’s products, recalls often lead to investigations that uncover underlying issues, leading to improved manufacturing processes and stricter regulations. By learning from these incidents, the industry can avoid repeating past mistakes, ultimately enhancing the safety of not just children but also users of all ages, as seen in instances like nursing home neglect or auto/truck accident injuries where product safety is paramount.

Impacts and Best Practices for Consumer Protection

Recalls play a pivotal role in safeguarding consumers, particularly vulnerable children, from potential harm caused by defective children’s products. When a product is recalled, it highlights the manufacturer’s commitment to consumer protection and ensures that any identified flaws or hazards are rectified promptly. The impact of recalls extends beyond the immediate removal of hazardous goods; they serve as a critical tool for fostering public trust and transparency in the market.

Best practices for effective recall processes involve robust quality control measures, proactive monitoring systems, and open communication with consumers. Manufacturers should establish clear procedures to identify potential defects, collaborate with regulatory bodies, and implement efficient distribution networks for timely product removal. Moreover, offering adequate compensation or replacement options, as well as providing educational resources about safe product use, can mitigate negative experiences related to defective children’s products. This holistic approach ensures consumer satisfaction, fosters brand loyalty, and ultimately contributes to a safer marketplace, minimizing the occurrence of auto accident injuries linked to faulty products.

Recalls play a pivotal role in mitigating risks associated with defective children’s products. By swiftly removing hazardous items from the market, these actions protect young consumers and prevent potential injuries or worse. Understanding the importance of recalls is essential for fostering consumer confidence and ensuring the safety of our youngest population. Effective recall processes, coupled with robust product safety standards, are indispensable tools in safeguarding children and promoting a safer environment.